QIS Classic

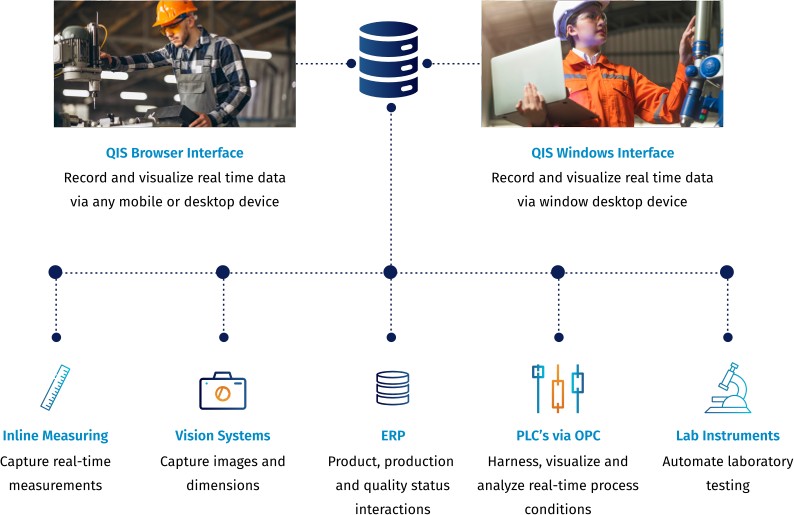

QIS Classic delivers a full range of functionality via

a traditional server/client environment.

Providing complete visibility of real-time, statistically based intelligence throughout your manufacturing process, QIS helps drive critical and immediate in-line decisions and provides the analytical tools required to support longer-term strategic improvement goals.

Key Features

Advanced functionality supports digital transformation and paperless operations across quality and production

Quality Control & Compliance

Ensure product quality and consistency

COA Production

Cut out paperwork, duplication and costly mistakes

High Frequency Data

Identify and respond to changes in your process

Automated Downtime Tracking (OEE)

Prevent downtime, performance and quality losses

Advanced Integration

Connect to third party systems, lab instruments and more

Alarms & Notifications

Your early warning system, before there is a problem

While making it simple to provide management with the data and KPI reports they require, QIS is also focused on giving operators, process engineers, quality teams, lab techs alike access to real time, statistically based intelligence to support critical decision making.

The range of QIS key capabilities benefit our customers worldwide by providing one solution to help them improve product consistency, optimize process efficiency, and provide critical information across the manufacturing operation to prevent quality losses and reduce costs. Ultimately helping deliver a superior customer experience.

Customer Configurable

Available out-of-the box, this highly configurable solution is easy to use and quick to deploy across the factory floor, the laboratory and beyond.

Paperless Environment

Create a paperless environment across your production and quality departments. Streamline internal process and procedure.

Data Driven Decisions

Improve the accuracy and availability of data to support decision making across production, process control and quality – from suppliers through to customers.

Who its Good For...

QIS was designed to complement and enhance a manufacturing site’s day-to-day practices, giving operators, process engineers, quality teams and lab techs alike, access to real-time, statistically based intelligence for everyday use and benefit.

Using a specialized real-time data collection system, such as QIS, can help remove the errors and delayed feedback inherent in complex or disconnected systems; a key step in eliminating waste, reducing quality losses and supporting continual process improvement.

Data Integration

QIS Classic features extensive options for automatic data capture from 3rd party data sources. Large volumes of data can be recorded on an event or time basis, providing high data integrity for detailed process understanding and analysis. Alternatively, QIS data can be passed to other process or business systems for efficient data management and site-wide access.

Most interface management services run on servers or process networks that regular users do not have access to. The QIS Interface Console provides all authorized users the ability to seamlessly view all logs and any related local settings and the ability to make changes from one location (with the correct rights assigned). For initial set up, re-configuration or any troubleshooting, access to pertinent logs is quick and easy.

Example On-Premise Pricing

Starter

$35,000

£25,000

€30,000

Quick Start - Limited Users

- Get up and running in less than 4 weeks

- 5 user concurrent license

- Full access to core system

- Basic implementation services

Mid-Size

$50,000

£40,000

€54,000

Increased Users - Expanded Set Up

- 15 - 20 user concurrent license

- Full access to core system

- Access to added value modules

- Expanded implementation services

Advanced

$75,000

£65,000

€70,000

Max Users + Integration

- 40+ user concurrent license

- Automated data capture - integration

- Access to added value modules

- Advanced implementation services