QIS Cloud

Create a paperless environment across your production and

quality departments, quickly and easily.

Hosted on the AWS platform, QIS Cloud offers flexible subscription-based pricing without the need for significant IT infrastructure and resource.

Key Features

QIS in the Cloud delivers the full QIS user experience via the flexible and secure Amazon Web Service platform (AWS).

The infrastructure is designed and managed in alignment with industry best practices:

Security

Partnered with AWS. End-to-end data security is paramount throughout QISOFT CLOUD.

Scalability

Designed to grow with you, QISOFT CLOUD enables manufacturers of all sizes to benefit instantly from unsurpassed functionality.

Easy Deployment

With no need for internal server and minimal hardware requirements. QISOFT CLOUD takes the burden away of your internal IT.

Accessibility

All you need to get started is a web enabled PC, Laptop or tablet plus a few hours training from one of our gurus.

Affordability

With no hefty upfront hardware costs and significantly reduced maintenance costs QISOFT CLOUD provides manufacturers a flexible and affordable solution.

Maintenance

With access to the most up to date software versions users instantly benefit from new features and functionality without software or hardware updates.

Digital transformation strategies support efficient manufacturing and can help meet increasing demands for faster delivery, heightened production and give organizations a competitive edge.

As the manufacturing industry moves further to embrace this, it is becoming clear that cloud computing can help make digital transformation possible for any size company – quickly and cost effectively.

Rapid Set Up

Start securely capturing and analyzing your manufacturing data with set up in as little as a few hours.

Anywhere, Anytime

Access your system from any internet enabled device – at home, at the factory or on the move.

Immediate Benefits

Identify and address quality issues early in the process, resulting in less scrap, rework, recalls and returns.

Who its good for…

- Production Manager

- Quality Manager

- CI Manager

- Operator

“Higher productivity was achieved from faster machine speeds made possible by closer control of wet end conditions. Automated process monitoring continues to give greater accuracy and reliability of data over manual methods and allows for built-in compensation where the system detects variability in measurement.”

Production Manager – Paper Mill

“The real challenge is to sustain the right level of product quality with an optimum output and against minimum costs. Therefore, we must spend energy on improving our knowledge of all different parameters in the production process and their interconnectivity. QIS plays an important role in this.”

Quality Manager – Global Tissue / Forest Products Business

“The analysis features in QIS have helped identify many causes for product quality deviations. Warped peppermint tablets occurred especially when production rates were high and a lot of sugar was being used from the sugar mills. Once this was identified the root cause of the problem became clear quite soon: the ground sugar became too warm when the demand for sugar was high. The solution was simple – cooling the sugar mills.”

Continuous Improvement Manager – Candy Manufacturing

“There is a user-friendly advantage of QIS that other systems just don’t have. QIS has a familiarity that the plant workers really appreciate. It has been upgraded over the years and is technologically on point, yet it’s still so easy to use that it is never intimidating to anyone. Not only does QiSOFT help improve the Mill’s process and product quality, it makes the shop floor hungry for data, involving them more heavily in the process, which, in turn, makes them more invested in the solution.”

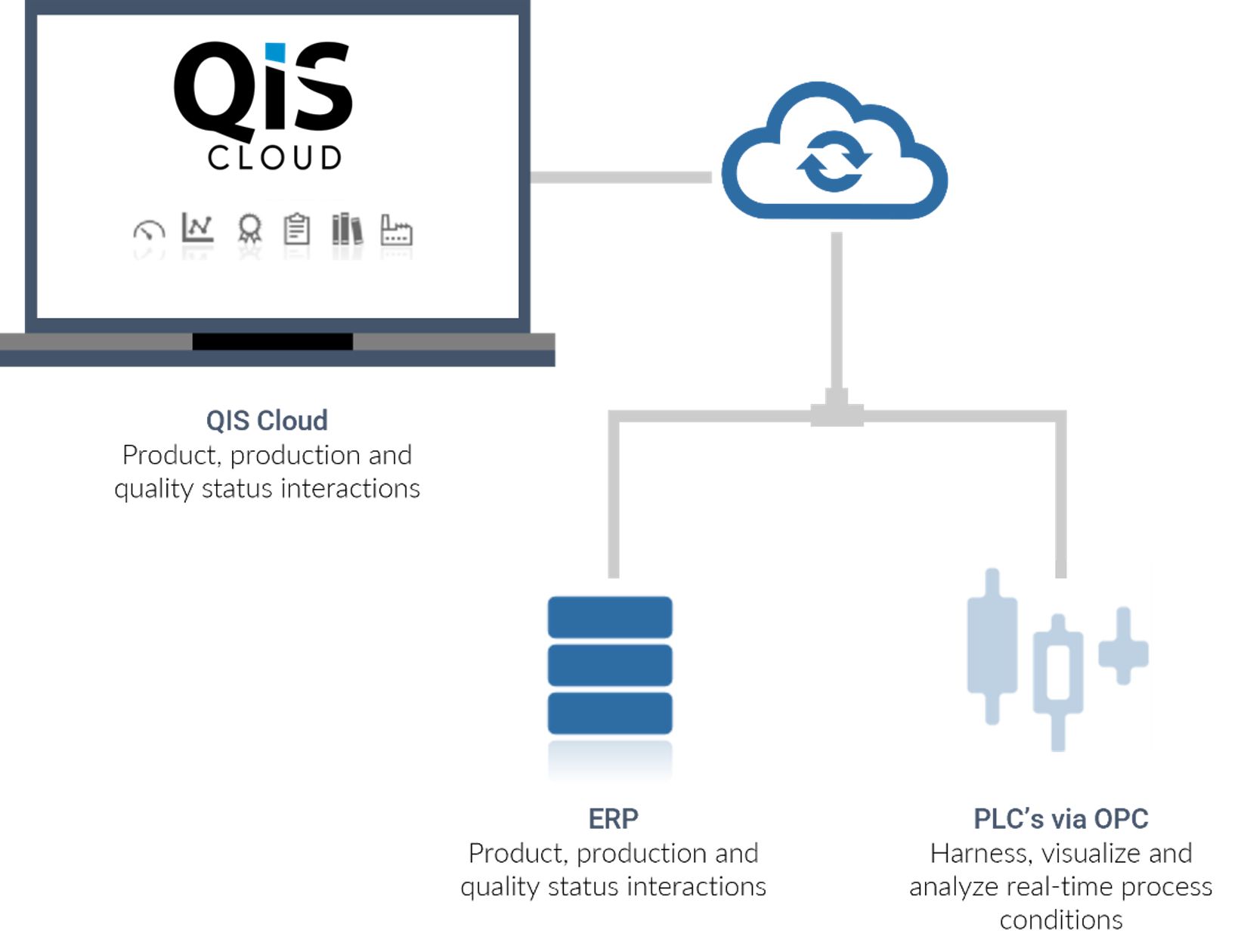

Cloud Data Integration

Communicate and exchange data with 3rd party systems and applications via DataLink for in-cloud solutions.

Real-time automated data collection takes the pressure off operators and provides the accurate data you need to support your operational needs. QIS can be connected directly to your control systems or inline measuring and monitoring systems.

ERP Integration can provide product, production and quality status interactions. While PLCs via OPC can harness, visualize and analyze real-time process conditions. When data is required it will be automatically logged in QIS and will appear on your operators console for review.

Example Pricing Plans

Starter

$625

£500

€600

Quick Start

- 5 QIS cloud named users

- Assisted set up and configuration

- Remote training and guidance

- 24-7 support and E-learning access

Mid-size

$1,500

£1,500

€1,500

Mid-Size Factory

- 15 QIS cloud named users

- Assisted set up and configuration

- Remote training and guidance

- 24-7 support and E-learning access

Advanced

$2,250

£2,250

€2,250

+ Data Integration

- 20 QIS cloud named users

- Exchange data with 3rd party systems

- Assisted set up and configuration

- 24-7 support and E-learning access